Ultrasonic Welding

Ultrasonic welding service available on a range of polymers and can be incorporated in line with injection molding. Ultrasonic welding, for thermoplastic injection moulded components, is a process that uses mechanical vibrations above the audible range. The vibrations, produced by a welding sonotrode or horn, as it is generally known, are used to soften or melt the thermoplastic material at the joint line.

Mould / Parts Painting

Our plastic injection molding design experts can help you choose the most efficient painting process that will deliver the results you need for your parts and end product. With consistent success, we’ve utilized the following methods on injection molding projects for our customers – Spray Painting, Powder Coating, Silk Screening, Stamping, In-Mold Painting.

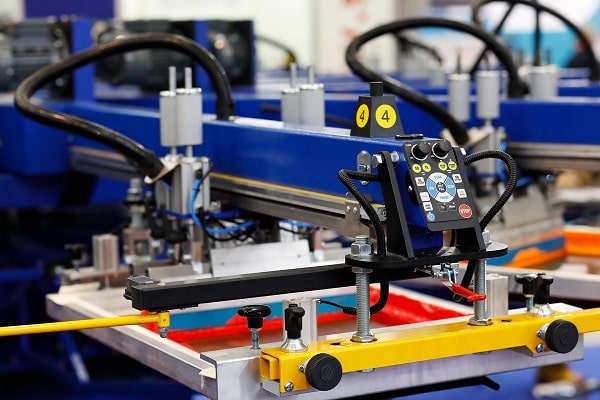

Screen Printing

Offering the most advanced silk screen printing processes for plastic parts. If you require color matching, patterns, logos and other specifics, an injection molding secondary process may be needed. Silk screen printing can add details, images, text and logos to a part. In addition to the many painting options available through our specific systems and processes, silk screen printing plastic injection molded parts can be a desirable option when multiple colors are part of the part design.

Hot Stamping & Hot Foiling

Hot stamping or foil stamping is a printing method of relief printing in which pre-dried ink or foils are transferred to a surface at high temperatures. Special ink or foil finish available in the hot stamping facility. This operation includes robotic control to speed up the handling process..

Chrome Plating

Chrome plating is a process of electroplating chrome onto a metal or plastic product. Chrome plating is a post moulding operation and can be done for decorative or industrial purposes.

Some of the benefit of chrome plating is it provides resistant to corrosion, it cleans very easily and helps increase the hardness of a surface.

FAQ

Are you trading company or manufacturer ?

We are manufacturer of injection and blow moulded products.

How long is your delivery time?

According to the difficulty and quantity of product processing,a reasonable arrival time will be given to you.

Do you provide HDPE end cap samples ? is it free or extra ?

Yes, we could offer the samples for free charge.

How can we guarantee quality?

We do pre-production sample before mass production. We do final Inspection before shipment;